What Track and Trace Equipment Does Each Participant Need?

To meet regulatory standards, market participants should select equipment based on their operational requirements.

Laser Goods Marking Equipment

Laser goods marking equipment is an ideal choice for manufacturers, as it helps avoid DataMatrix code damage much more effectively. High-speed and accurate laser marking systems allow manufacturers to apply DataMatrix codes directly onto products or packaging.

This technology allows:

- 1Applying up to 30 codes per second, ensuring high marking quality and the number of errors reduced to a minimum

- 2Working without expendable materials

- 3Extending the period of service up to 100 000 hours, very little maintenance and few cases of unplanned shutdowns

- 4The use of all types of lasers for various purposes: fiber, UV, and CO2

- 5Automatic DataMatrix code generation with a built-in data buffer.

- 6Seamless integration with various systems and devices

- 7ZPL format support

- 8Data transmission via the TCP/IP protocol

- 9Increased bandwidth due to a large processing area

Inkjet DataMatrix Printers

Another option for manufacturers is purchasing a thermal inkjet printer — a non-contact printing device that uses heat to propel ink droplets onto a surface. This equipment is less expensive than the laser one, yet still efficient enough to be a great choice for small- and medium-sized businesses.

Inkjet DataMatrix printers are suitable for coding and marking on plastic bottles, plastic bags, laminated sheets, coated boxes, aluminum cans, metals, and other non-porous materials.

It has the following benefits:

- 1Equipped with advanced coding technologies that ensure low costs and simplify manufacturers’ marking needs

- 2No regular engineer maintenance is required. Troubleshooting can be done remotely or with the help of an online manual

- 3Easy to use thanks to Wi-Fi connectivity, allowing manufacturers to quickly create messages and manage the printer from any device

DataMatrix Sticker Printers

Manufacturers can use high-quality printers that produce DataMatrix code stickers. Those stickers are either applied to products directly (serialization), or used during the aggregation process — linking individual items or units together into a larger, parent unit — by adhering them to boxes, pallets, etc.

These printers are a good option for micro- and small businesses, as it’s not as costly as laser goods marking equipment. They support variable data printing to customize each label with unique codes, batch numbers, or expiry dates.

DataMatrix Code Scanners

High-performance scanners facilitate quick and precise scanning of incoming goods, enabling real-time updates and seamless inventory management at receiving points.

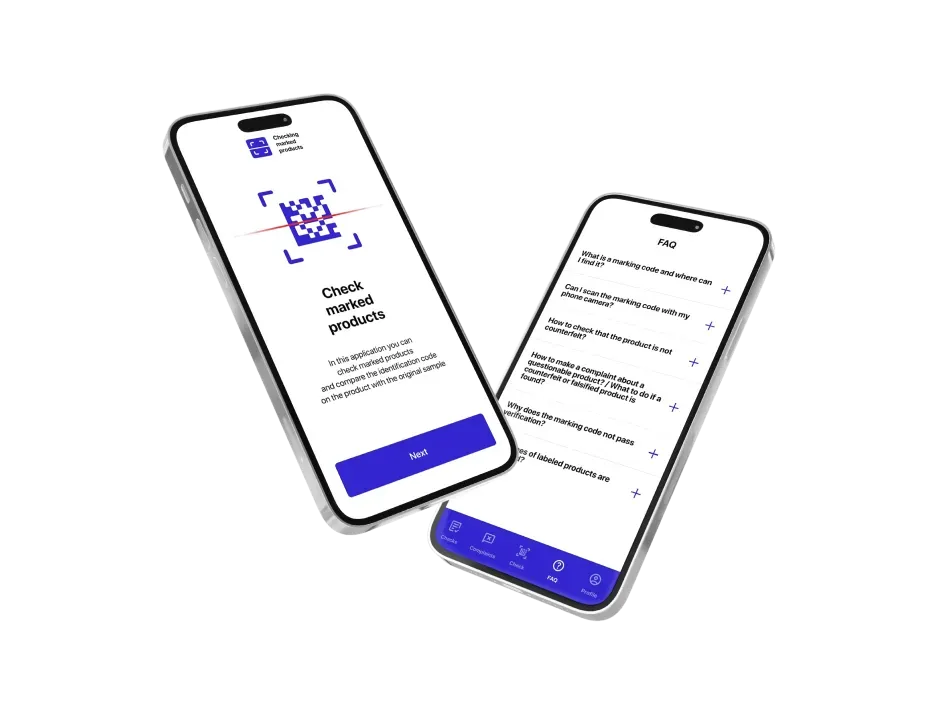

Mobile App

To enhance visibility and streamline operations, manufacturers will benefit from a dedicated mobile application designed for Track and Trace systems.

Such an app can fully replace traditional scanners and provide instant access to critical product information right on the production floor, offering real-time data capture, operational flexibility, seamless integration with other systems and reporting